TPA permanent magnet synchronous motor on the screw air compressor Application not only extends the life of the host, But also to achieve the effect of green energy.

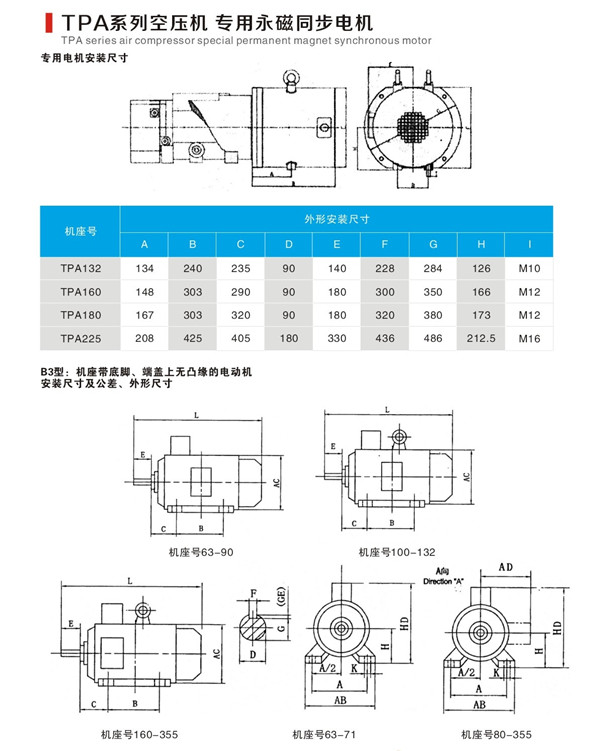

Special Permanent Magnet Synchronous Motor for TPA Series Screw Air Compressor

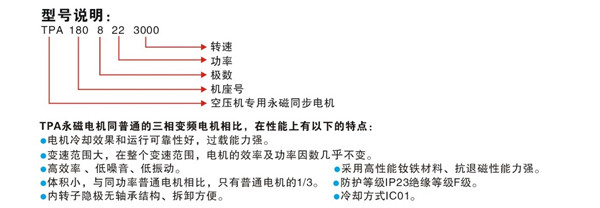

1 Overview

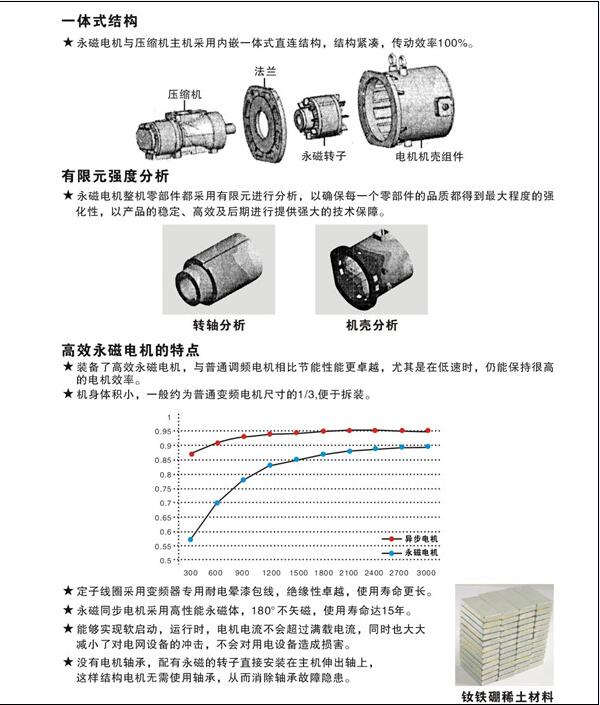

In order to meet the screw air compressor in the operation of energy-saving requirements, our company has carefully developed a TPA permanent magnet synchronous motor. When the air compressor is in a partial load, the motor can change the speed with the air, and still maintain high efficiency, when the air compressor full load operation, the motor can run efficiently. TPA series of air compressor dedicated permanent magnet synchronous motor using high-performance NdFeB permanent magnet, 180 ° without loss of magnetic, compared with the ordinary FM motor, energy-saving performance is more excellent. In the low-speed operation, still able to maintain a high motor efficiency, energy efficiency to meet GBI8613-2012 motor-level energy efficiency standards.

Motor stator coil with inverter special corona enameled wire, excellent insulation, longer life, can achieve soft start, the running current will not exceed full load current, but also greatly reduced the impact on the power grid equipment, not on Electrical equipment damage. The motor is equipped with direct bearing without bearing structure, compact structure, transmission efficiency of 100%. Fuselage small size, generally about the size of ordinary FM motor 1/3. The motor rotor is mounted directly on the shaft of the compressor head, which is simple and convenient for dissemble and eliminates the hidden trouble of the motor bearing failure.

2. Basic parameters

Rated voltage: 380V

Rated frequency: 50HZ

Power range: 7.5-90KW

Insulation class: F

Protection class: IP23

Cooling method: IC01

Installation: IMB3

3. TPA series of air compressor dedicated permanent magnet synchronous motor in the application of air compressor: